As is with many other facets of an automobile, the modern version of the fuel delivery system is much different than decades previous. As typical as it may be, it is particularly important to be aware of, especially when looking to diagnose a problem. Whether it is for a ’57 Chevy, or a 2010 Toyota, when getting to know the fuel delivery system you are working with, it is imperative that you know its working parts. For the sake of modernity, let’s focus on more modern versions of the fuel delivery system, and the parts that make it function.

Volume and Pressure

In modern fuel delivery systems, the fuel pump is largely driven by the volume and pressure of the gas that is supplied by the fuel pump relay. In essence, it is the job of the relay to create adequate pressure and fuel volume in order to ensure proper fuel pump output.

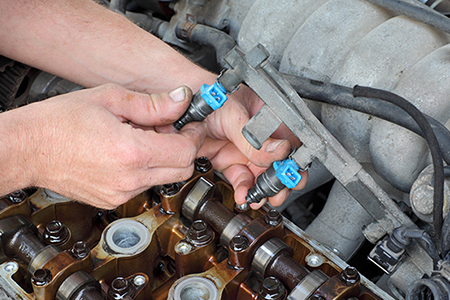

After the fuel pump relay serves its purpose, next to the part that influences pressure and volume is the electric fuel pump. More specifically, the electric fuel pump effectively creates enough pressure to essentially vaporize the fuel that is being used by the fuel injector. Both the fuel pump and fuel injector are protected by filters — the fuel injector is protected by a fuel filter, while the fuel pump is protected by a fuel strainer, which sifts out dirt as it is attached to the fuel inlet.

Pulse Modulated Fuel Delivery

When getting to know a fuel delivery system it is also important to know the pulse modulated aspect. Essentially, pulse modulation eliminates the function that has traditionally been reserved for a fuel pressure regulator. A pulse-modulated delivery system controls the speed of the fuel pump in order to alter fuel pressure, thus making a regulator largely obsolete. With that said, however, a pulse-modulated system does not come full of simplicity, as it needs a diagnostic scan tool, as well as a fuel pressure sensor (utilized by the powertrain control module) to function properly.

The fuel delivery sensors — which are primarily used in pulse-modulated systems — are aimed at creating an atmosphere in the combustion chamber that is symbiotic with both air and fuel. Also previously mentioned is the diagnostic system that is built-in with the powertrain control module. Such diagnostic systems are usually quite elaborate and vary depending on the automobile. More concisely, these diagnostic systems are used to not only monitor the performance of the fuel delivery system but also to identify and diagnose any problems that may occur throughout the process of delivering fuel to the engine.

![[OE Auto Parts] - FJ475 OE Performance fuel injectors sold by Pjvmvo are OE parts.We use VIN matching to ensure the integrity of our inventory and accuracy of product descriptions.Offer high quality, and long-lasting performance. [Fitment] - 4.7L-V8 ...](https://m.media-amazon.com/images/I/41sG0Q96eaL._SL100_.jpg)

![[Vehicle Fitment-1]: Compatible with Dodge B1500 1996-1998 V8 5.2L, 1998 V8 5.9L, B2500 1996 V8 5.2L(GAS), 1996-1998 V8 5.9L, 1997 V8 5.2L, 1998 V8 5.2L(GAS), B3500 1996 V8 5.2L(GAS), 1996-1998 V8 5.9L, 1997 V8 5.2L, 1998 V8 5.2L(GAS), Dakota 1996 V8...](https://m.media-amazon.com/images/I/51AcavYe8kL._SL100_.jpg)

![[Vehicle Fitment-1]: Compatible with Chrysler 200 2011-2014, Sebring 2007-2010, L4 2.4L; Compatible with Dodge Avenger 2008-2014, Caliber 2007-2012, L4 2.0L/2.4L, Journey 2009-2015 L4 2.4L [Vehicle Fitment-2]: Compatible with Jeep Compass 2007-2017, ...](https://m.media-amazon.com/images/I/41rHvMw6ycL._SL100_.jpg)

![[Vehicle Fitment-1]: Compatible with Buick LaCrosse 2010 V6 3.0L, LaCrosse 2012-2016 V6 3.6L, Enclave 2018-2021 V6 3.6L, Allure 2010 V6 3.0L; Compatible with Cadillac ATS 2013-2015 V6 3.6L, CTS 2010-2014 V6 3.0L, CTS 2012-2015 V6 3.6L, SRX 2010-2011 ...](https://m.media-amazon.com/images/I/51WBMk0K7sL._SL100_.jpg)