The throttle position sensor (TPS) detects the position of your throttle and sends this along to the car’s computer. If the sensor’s mechanical parts become worn, then bad data is submitted, causing the computer to make incorrect decisions and, in turn, leading to poor fuel economy and other issues, some of which could mimic problems with the fuel delivery system.

Symptoms of a Faulty Throttle Position Sensor:

Since a bad TPS causes so many problems, a faulty sensor often goes undiagnosed. To make things more complicated, these problems often appear only after the engine and TPS are warmed up. Typical symptoms of a poorly functioning TPS include:

- A large drop in fuel economy

- Sudden surges during idling or a high idle condition

- Unexplained jerking and bucking

- Sudden engine stalls

- Surges in speed during highway driving

- Stumbling during acceleration

- Inconsistent flashing of the “check engine” light

- Difficulty changing gears

- Troubleshooting a Throttle Position Sensor

These instructions are for a TPS that uses a potentiometer; you’ll need a multimeter.

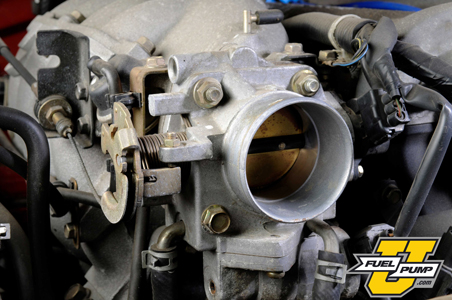

- Open your hood and find the TPS; you’ll see a black box next to the throttle body with three wires emerging from the electrical connector.

- Unplug its electrical connector, then switch on the car’s ignition without starting the engine.

- With your multimeter set to volts, probe the terminals on the computer side of the TPS to check the supply voltage. The negative lead should touch the terminal ground (black wire) while the positive (red) lead goes to the terminal reference voltage wire (gray or blue). You should get a Content Preview constant of 5.0 volts; if not, then there’s a short or an open in the supply wire. Switch off your ignition and plug the electrical connector back into the TPS.

- Check the signal voltage from the TPS to the car’s computer. Insert one pin through your ground wire and another through your signal voltage wire. Using alligator clips, connect the voltmeter probes to the pins, then turn on the engine. Watch the voltage reading while manually opening and closing the throttle plate; the voltage should gradually rise and fall, ranging from 1 to 5 volts. If the voltage signal shows no movement or erratic movement, then you’ll need to replace the TPS. Switch off your engine.

- Check the TPS resistance. Unplug the electrical connector again. Set the multimeter to ohms, then connect the probes to the wire contacts for the supply and signal. As before, watch the reading while manually opening and closing the throttle plate. The resistance should rise and fall gradually; if you find no change, an erratic change, or no resistance, then you need a new TPS.

- Adjust your TPS; some require periodic adjustments. Check your vehicle service manual for the proper resistance levels and adjustment techniques. While the ohmmeter is still connected, loosen the mounting screws and rotate the TPS until you get the resistance reading specified in the manual. Then tighten the mounting screws and test the resistance again as described in step 5 above. Plug in the electrical connector, turn on your engine, and test its performance.

![[OE Auto Parts] - FJ732 OE 5.7L Performance fuel injectors sold by Pjvmvo are OE parts.We use VIN matching to ensure the integrity of our inventory and accuracy of product descriptions.Offer high quality, and long-lasting performance. [Fitment] - 5.7...](https://m.media-amazon.com/images/I/51pCSQIeFnL._SL100_.jpg)

![[Application] Fit for 12V DC EFI system only. [Parameter] Test Flow: 200 LPH (75PSI & 12V);255 LPH (43 PSI&12V) ;300 LPH (43 PSI&13.5V). Operating Pressure:75PSI. Operating Temperature Range: -68 °F - 194 °F. [Medium] Compatible with gasoline, pump g...](https://m.media-amazon.com/images/I/41m3TTMgx8L._SL100_.jpg)