Types of Fuel Injectors

High Impedance Saturated Circuit Injectors

There are three styles of original equipment (OEM) fuel injectors. In each case, they are high impedance-10 to 17-ohm injectors and referred to as Saturated Circuit drivers and injectors. They all have a reaction time of 2 ms. They are relatively slow reacting, simple, very reliable, and inexpensive.

They operate from a 12-volt power source and use the controlled grounding from the powertrain control module (PCM) to energize. The main area of design that differentiates one from another is the nozzle design. The most efficient and widely used over the past 30 years is the pintle (needle and tapered seat). It is the least prone to failure due to varnish deposits.

The next most widely used injector utilizes a disc with multiple holes for fuel dispersion. It works well but is prone to plugging of the orifices by varnish. Both this and the pintle injectors are in wide use as OEM and are sufficient to flow enough fuel for applications up to 300 horsepower.

For high-performance applications over 300 horsepower, there is also a high impedance version with a ball and socket orifice. It has the capability to flow sufficient fuel for these higher horsepower applications. All of these high impedance saturated-injectors use low amperage, which keeps them cool and extends their longevity.

High-Performance Low Impedance Peak And HoldDesigned for high-performance use, these 2 to 5-ohm injectors flow a greater quantity of fuel than their counterparts. They use higher amperage and require a special dedicated computer for their operation. They differ from high impedance injectors in the amount of heat generated, a much higher fuel flow rate, and extremely rapid energizing. They slam open in 1.5 ms.

Symptoms Of A Bad Fuel Injector:

- Poor idle

- Engine miss

- Poor acceleration

Inspecting And Diagnosing A Faulty Injector

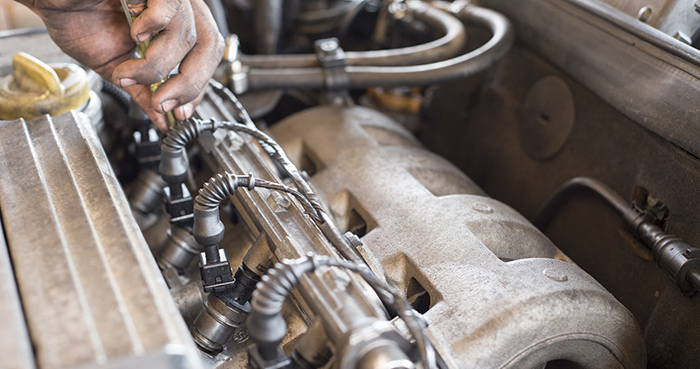

- Inspect each fuel injector for leaks. These occur at the point they are plugged into the fuel rail and sealed by two O rings, in the center body of the injector, and at the base where they are plugged into the intake manifold and sealed by two O rings.

- If the leak is in the injector body, remove and replace the injector and O rings.

- With the engine running, using a long screwdriver, hold it against each injector with the handle by your ear. Listen for the injector to have a steady metallic “ticking” sound.

- Compare the sound to the rest of the injectors. If an injector has an unusual or dull sound, replace it. If it is not ticking, pull the electrical connector off the injector.

- Using a noid light, connect it to the injector electrical connector. If the noid light blinks with the engine running, the PCM and wiring are good. Replace the injector. If the noid light does not blink, the wiring or PCM is at fault.

- If the injector is ticking, but there is an engine miss, pull the electrical connector off one injector at a time with the engine running.

- If the injector is good, the engine should run very rough as long as the injector is disconnected. Test each injector in this fashion, making a note of the one(s) that have little or no effect on engine idle. If an injector is found to have little or no effect on the engine’s idle, it may still be good and another problem may be causing the miss.

- Install a spark tester between the spark plug and the wire end. If the spark tester flashes with the engine running, shut it down and conduct a compression test. If the spark tester does not flash, repair the ignition problem. If the test proves the compression to be good, replace the injector.

Auto Amazon Links: No products found.